Precast Products

U - Drain Systems

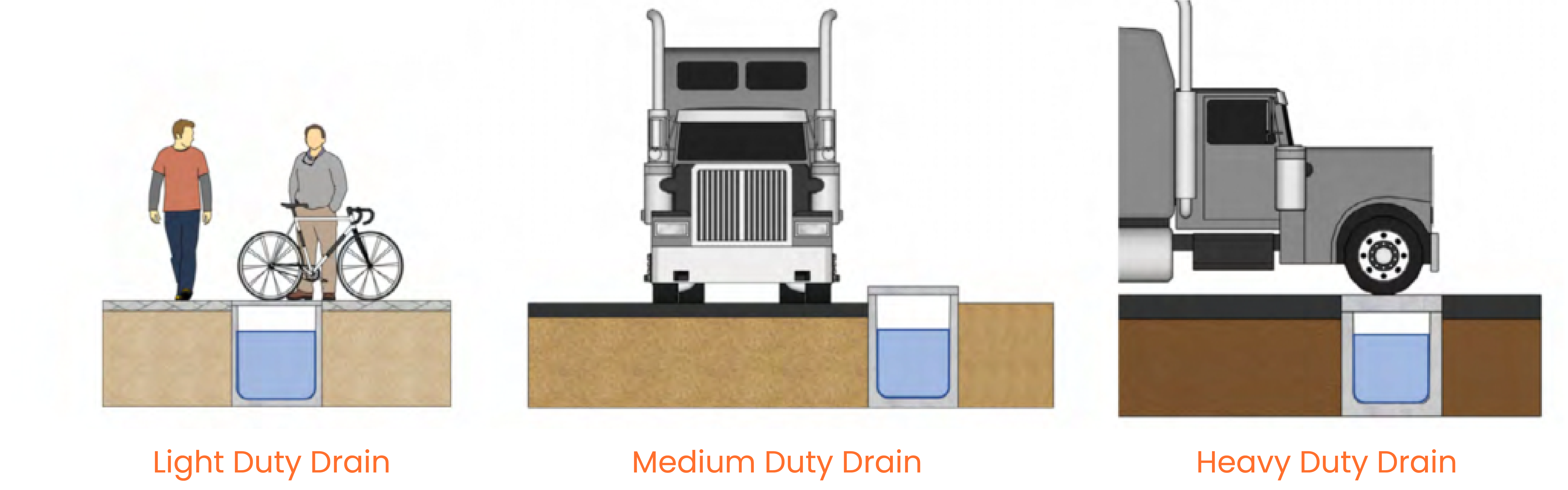

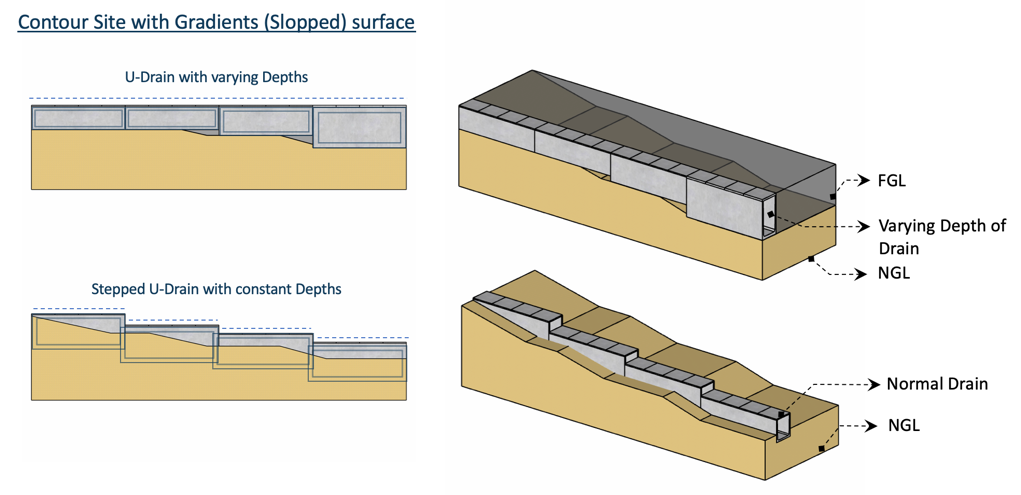

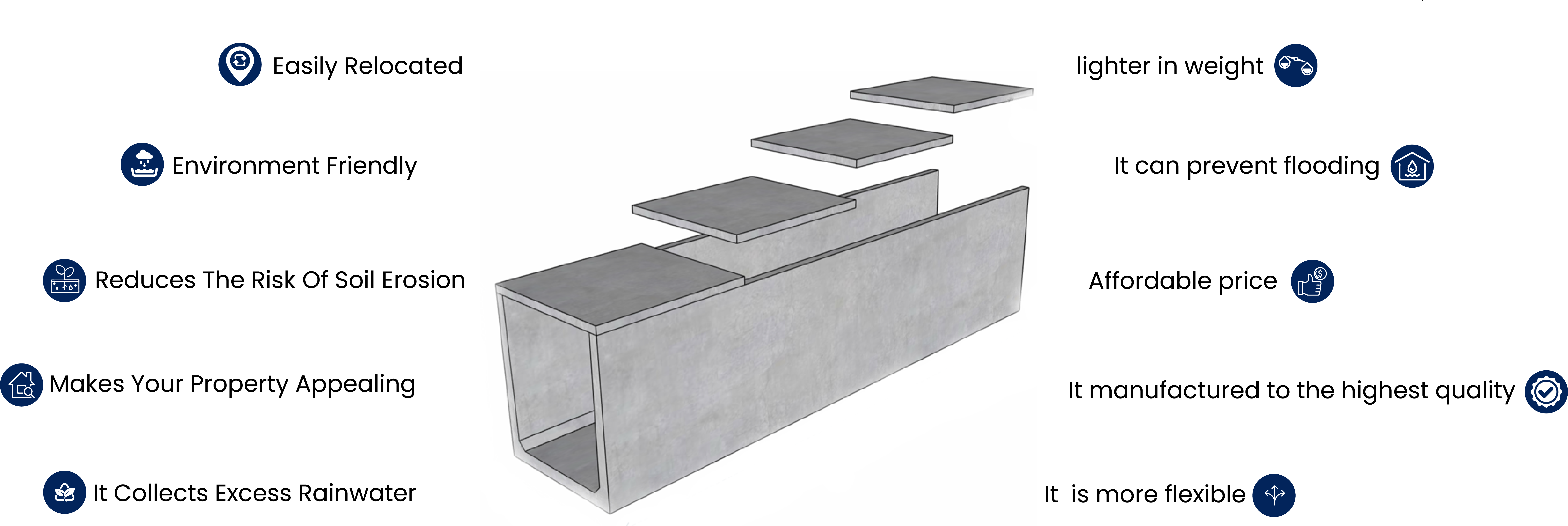

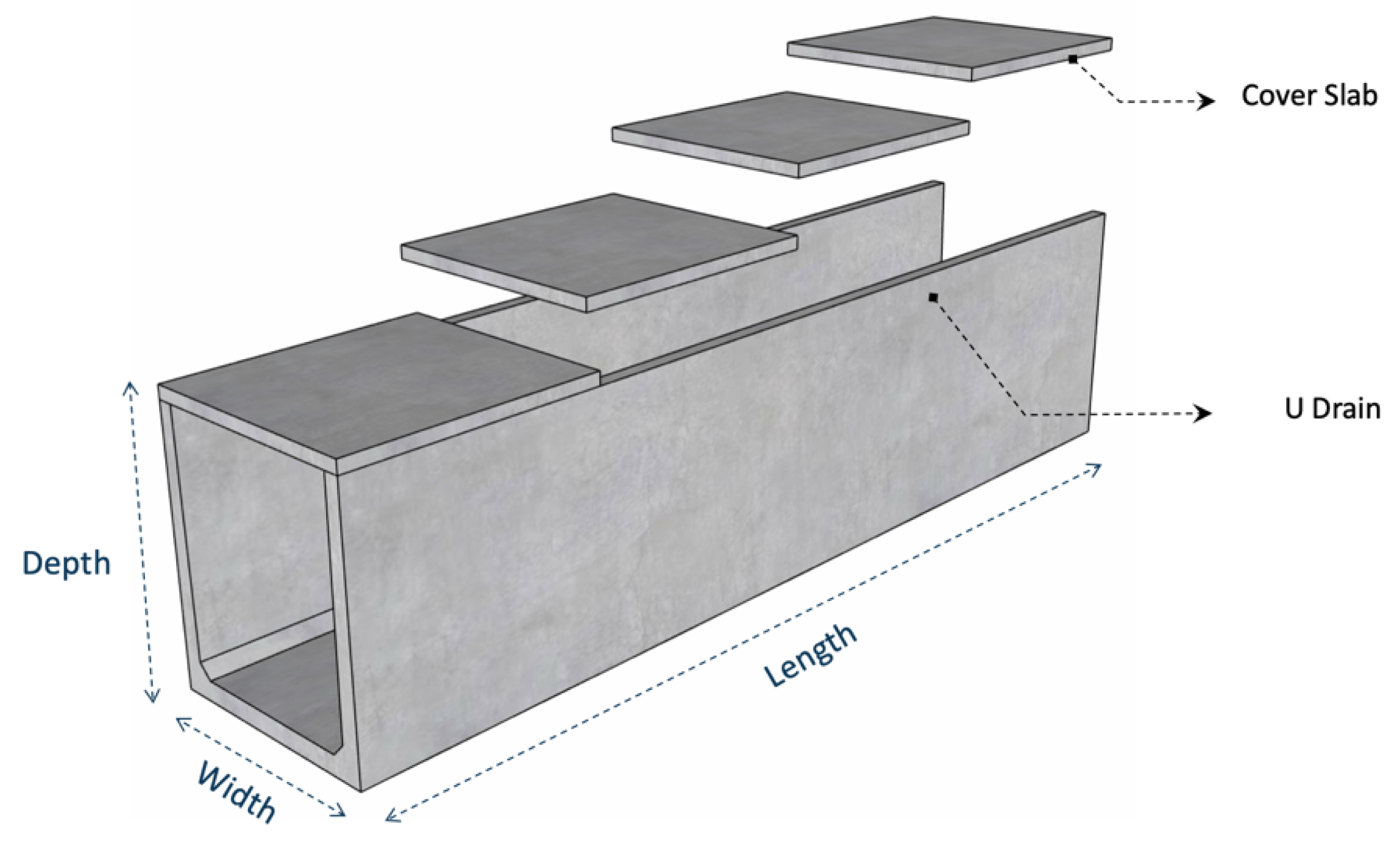

U-Drains are available in a wide range of sizes starting from 600 mm to 1500 mm in depth. They come with cover slabs, designed for various load conditions. Drains are factory-made, cast in a closed environment, have superior quality, and are well suited for fast-paced construction.