Precast Products

Boundary Wall & Retaining wall

Boundary / Compound wall is a simple DIY ( Do It Your Self) Product. Compound Wall is a basic need for any property to protect the land as well as structures built on the land.

Precast Products

Boundary / Compound wall is a simple DIY ( Do It Your Self) Product. Compound Wall is a basic need for any property to protect the land as well as structures built on the land.

Precast Products

Precast Products

Suitable For

Small quantity of water Storage

Over head storage

Utility

Toilets

Modular Units

Precast Products

The sizes of all these will vary based on the customer’s choice and based on the soil conditions and the land topography

Precast Products

In cases of clayey soil and high water table, it is preferred to go for a cast-in-place pile upto the NGL and then have a precast pile cap with a socket. The socket is cast along with the pile cap. Size of the pilecap is designed in a manner that it can accommodate a variation of 100mm along the X axis and Y axis respectively. Alignment of the socket is important, so that a straight line is got.

Precast Products

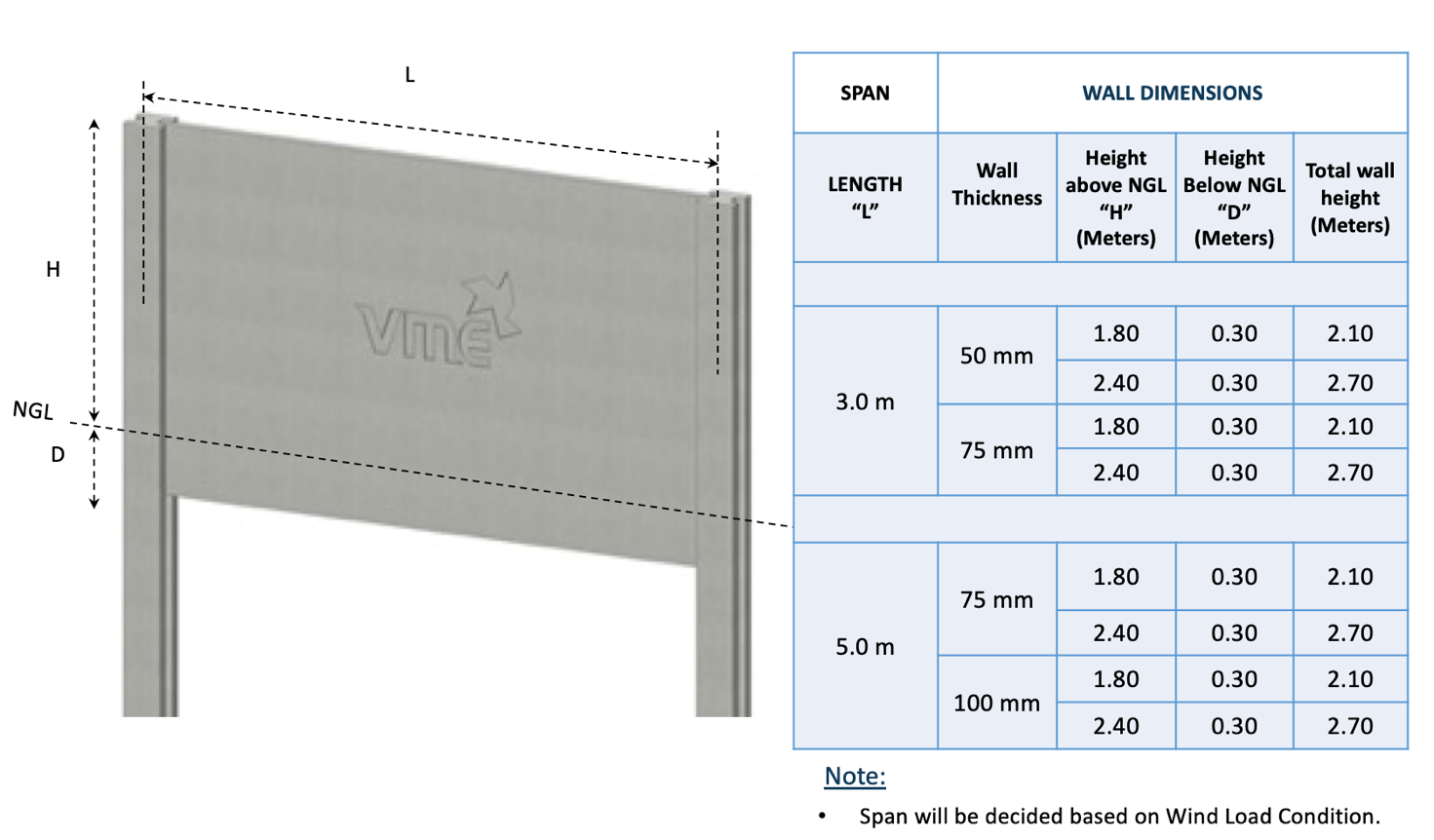

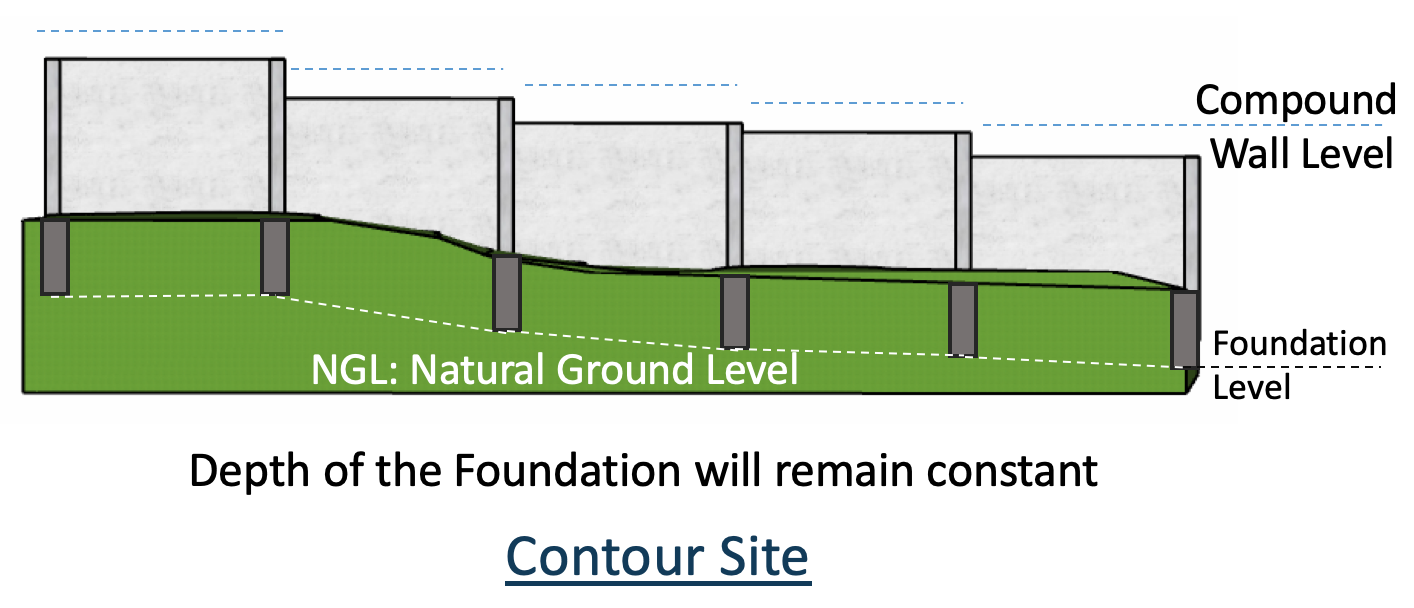

Based on topography of the land, height of the compound wall will change. Based on this, height of the column has to be arrived. If the client decides to maintain the same topography, then there will not be any change in height of the walls.

In case if the client wants to maintain a flat level, then there will be filling/cutting of land. In places, where filling is required, soil has to be retained, for which a retaining wall will be required. In such places we will have a retaining wall and compound wall slided into the columns. In majority of the cases, land fill will not be more than 2m.

Precast Products

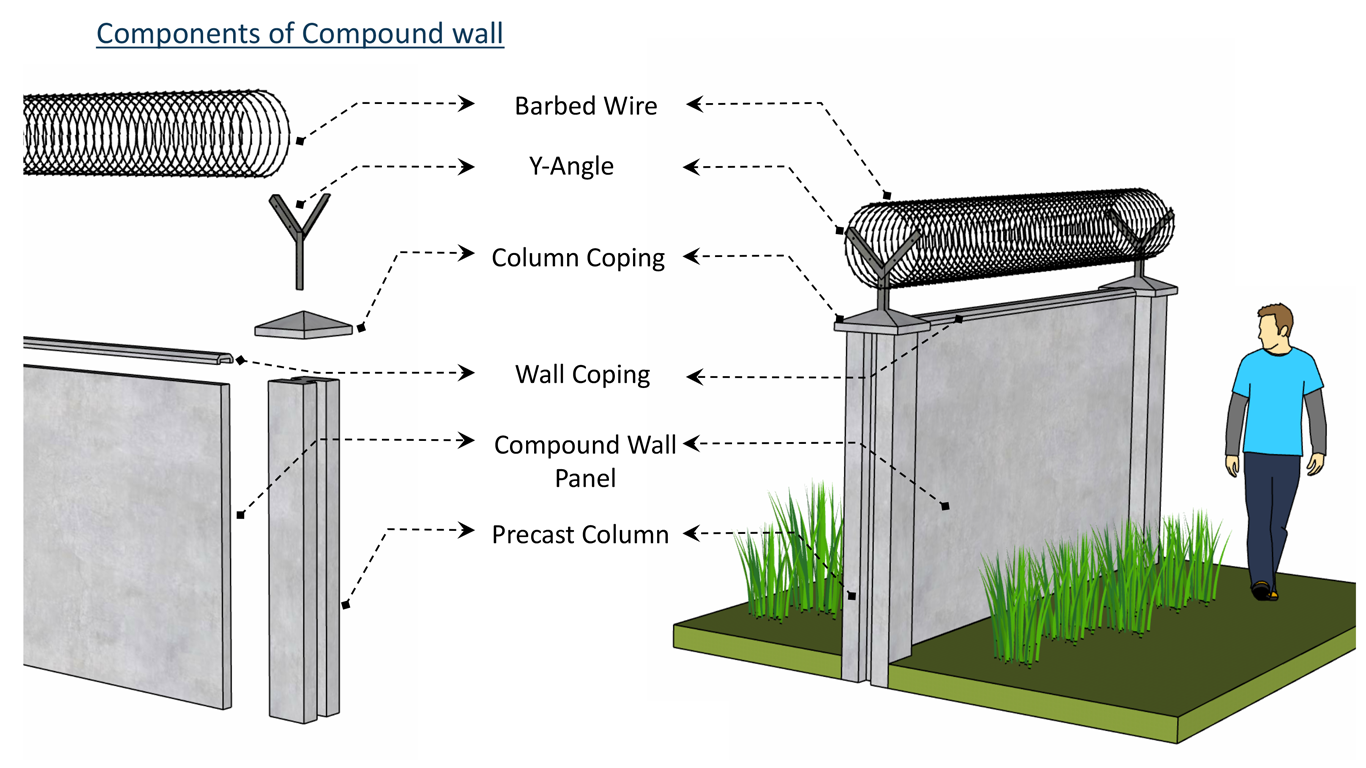

A precast RCC compound wall is a boundary wall made of reinforced concrete that is manufactured off-site in precast panels or sections and then assembled on-site to create a complete wall. These walls are commonly used to enclose and secure industrial, commercial, residential, and institutional properties.

• The industrial standards for precast RCC compound walls may vary based on regional or national building codes and standards. In some countries, the applicable standards could include:

• Indian Standards (BIS): IS 16737 - Precast Concrete Compound Wall - Specification.

It is essential to consult the relevant local building codes, regulations, and standards specific to your location to ensure compliance with the appropriate industrial standards.

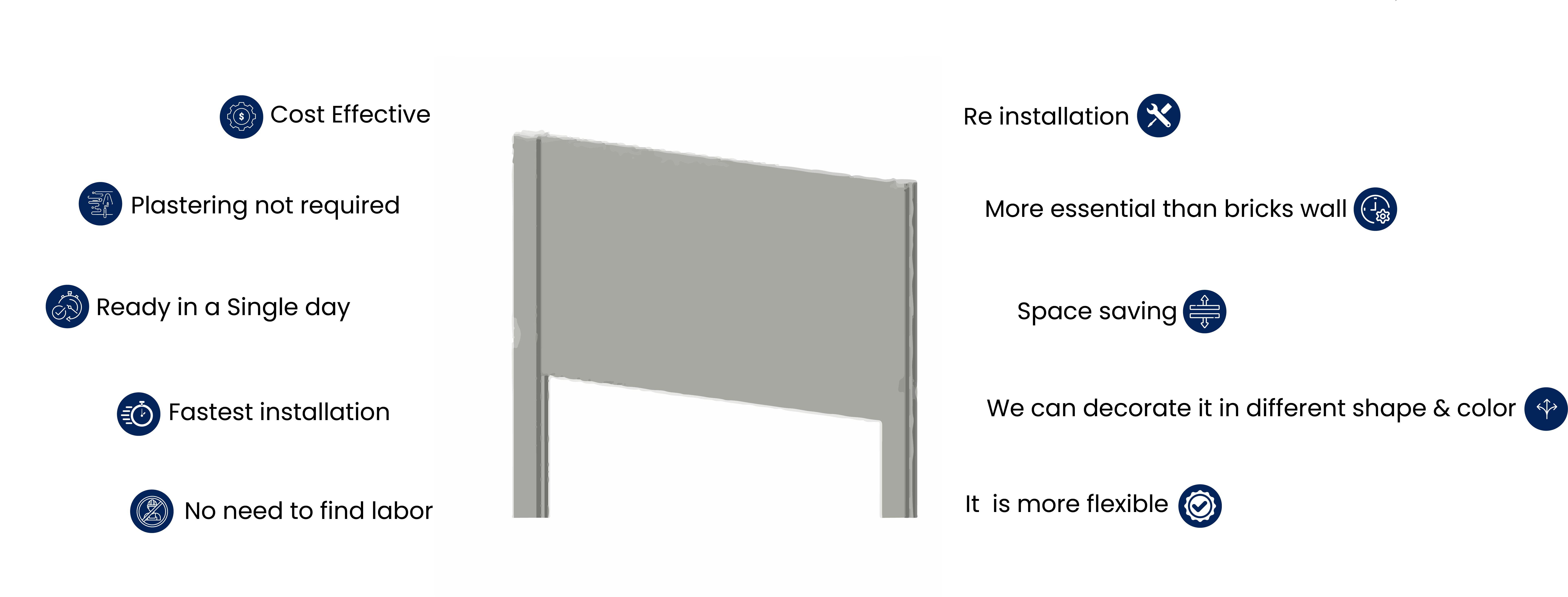

• Faster installation: Precast components can be manufactured off-site concurrently with on-site preparations, leading to quicker installation.

• Quality control: Precast components are produced under controlled conditions, allowing for better quality control and consistency

• Durability: RCC is a strong and durable material that can withstand various weather conditions, impacts, and wear over time.

• Cost-effectiveness: Precast RCC compound walls can be cost-effective due to reduced labor, shorter construction time, and optimized material usage.

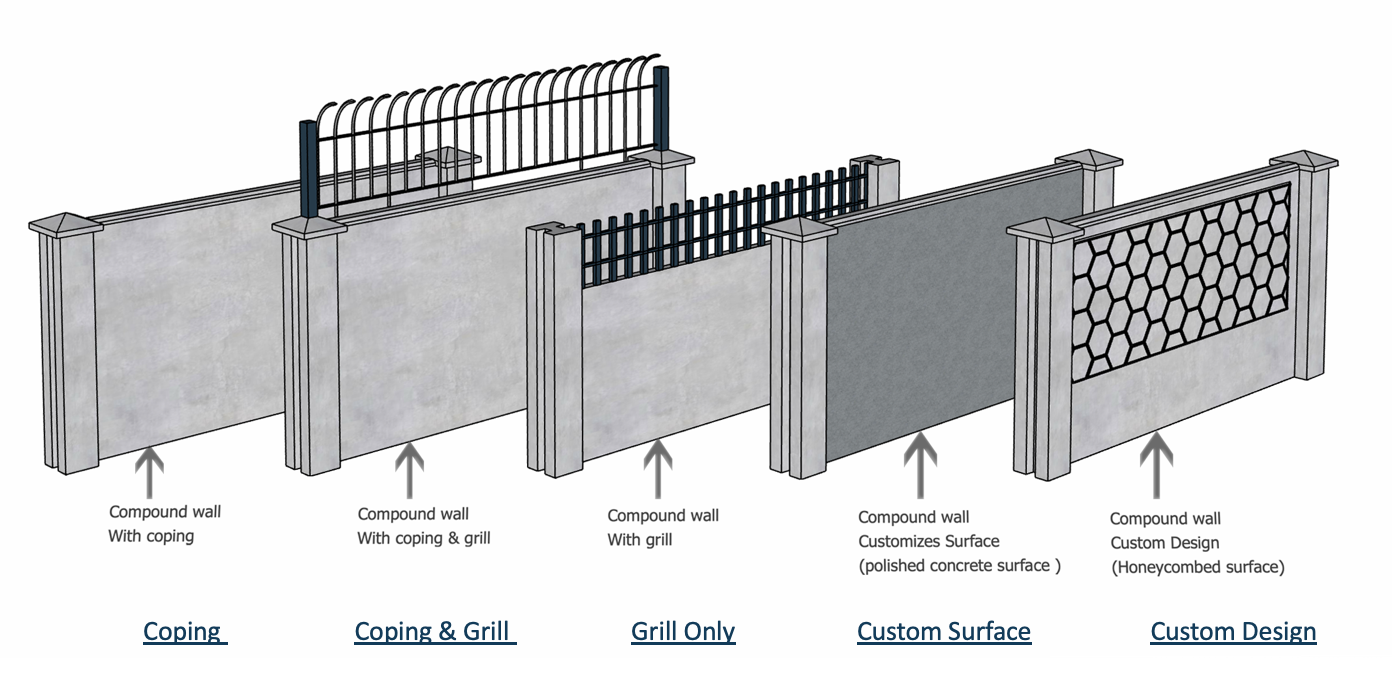

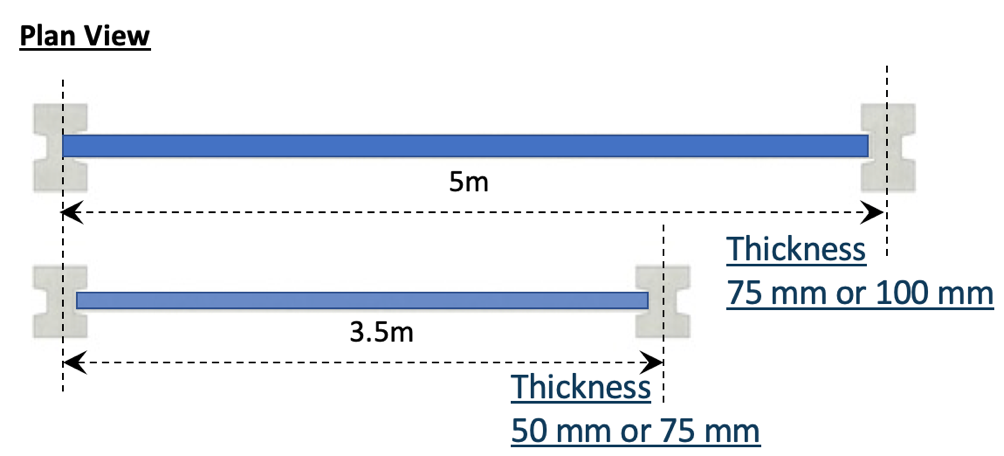

• Customization: These walls can be tailored to specific height, length, thickness, and design requirements.

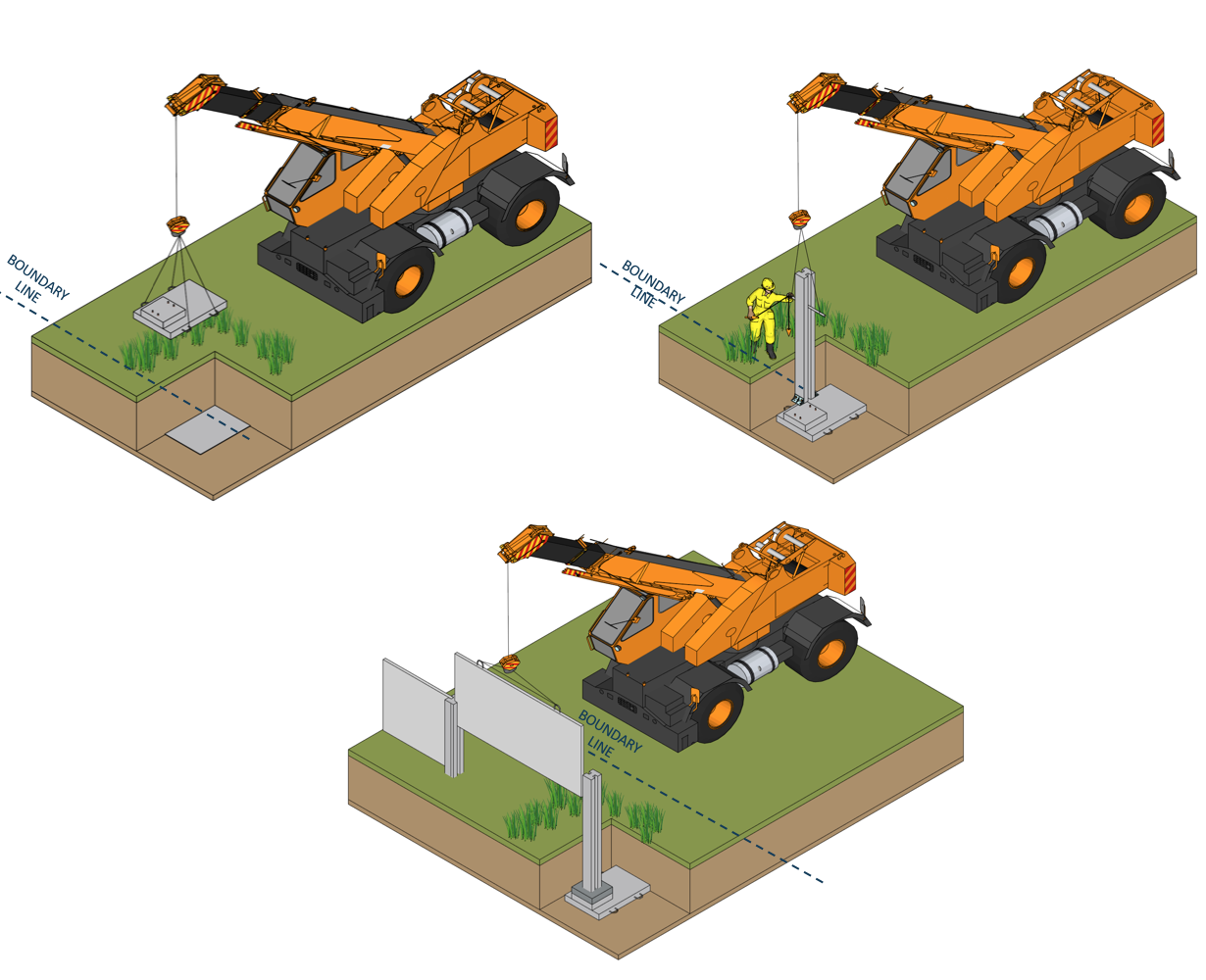

• Site preparation: The foundation trenches or footings are excavated and leveled to provide a stable base for the wall.

• Transportation and placement: The precast panels or sections are transported to the site and lifted into position using cranes or other suitable equipment.

• Connection and sealing: The precast components are connected and sealed using appropriate joints, connectors, and sealants to ensure structural integrity and stability.

• • Finishing: The wall's exterior surface can be finished with textures, patterns, or paint as per the design requirements.

The recommended height for precast RCC compound walls may vary depending on factors such as local regulations, security needs, and project specifications. In many cases, these walls can be designed and constructed to heights ranging from a few feet to several meters. It is crucial to consult local authorities and engineering professionals to determine the appropriate height based on specific project requirements and safety considerations.

Precast RCC compound walls typically offer a certain level of fire resistance due to the properties of reinforced concrete. RCC has inherent fire-resistant qualities, but the specific fire rating will depend on factors such as the wall thickness, design, and any additional fireproofing measures employed. It is advisable to consult with fire safety experts and comply with local fire safety regulations during the design and construction stages.

Copyright © 2023 Macon Precast

Developed by Chennai Publishing Services